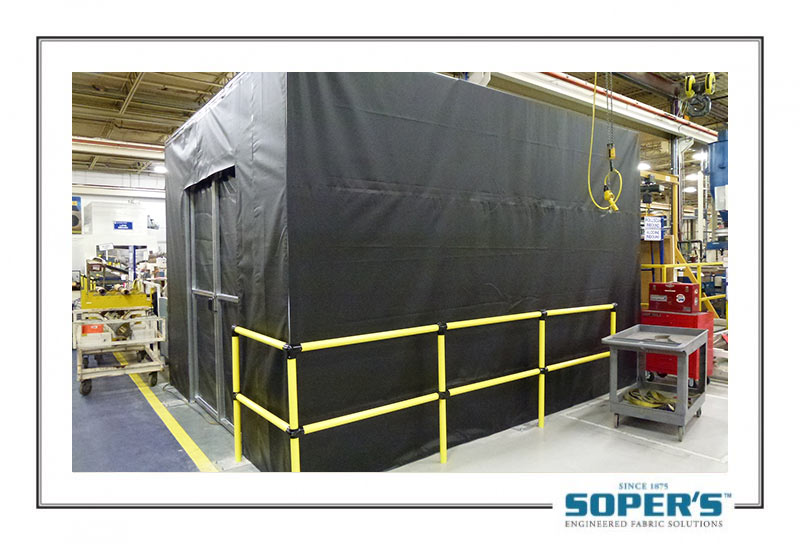

Soper’s Stationary SoftWall Enclosures effectively contain and control processes that can contaminate the workplace environment. Our SoftWall Enclosure booths start with a basic frame concept. Additional options such as lights, windows, and front curtain panels can be added. Our Enclosures easily integrate with third party dust collection or cross flow filter modules. Custom-designed to meet your specific application, Soper’s Stationary SoftWall Enclosures can also incorporate retractable roof panels to accommodate overhead crane cables or large bi-folding doors to maximize opening to load large pieces.

Applications

- Work stations

- Grinding

- Welding

- Sand or soda blasting

- Chemical stripping

- Blackout inspection

- Fabricating cells

- Assembly areas

- Painting rooms

Benefits

- Less dust, fumes, and other airborne particulate

- Improved employee health & safety

- Increased productivity

- Easy to install, dismantle, and relocate

- Economical

Features

- Modular in design and tailored to interface with specific material handling and processing operations

- Easily integrates with third party dust collection or cross flow filter modules or fan units

- Full range of SoftWall fabric panels available to meet a variety of unique requirements

- Velcro or fixed mechanical fastening options

- Optional access/door/roof panels

- Typical frames are 1 ½ or 2 sq galvalum steel tubing

- No painting required

- Easy thru-bolt field assembly

Request a Quotation

1.800.263.8334

Find out how we can create a custom solution for your business. Call us or submit a quote below.

Frequently Asked Questions

How do I determine which Soper's solution is right for me?

Our Soper’s team can help guide you in determining which solution will be best suited to your needs and requirements with one or more of our survey sheets. Our survey sheets can be found on our Resources page. Once we have received the initial input from your completed survey sheets, and if possible pictures of the potential installation area, we will go to work on developing some preliminary concepts.

Contact Soper’s today at 1-800-263-8334 or at info@sopers.com and we can help you get started!

What is your order turnaround?

The intricacy and size of the job requested will determine the length of time needed for approximate delivery. While times may vary, there are 3 levels of job categories that determine order turnaround time.

Level 1: When ordering stock items, your order will take approximately 2 days to process before shipment.

Level 2: For a standard (typical) curtain, one to two-day order entry, requiring at least one more day for drawing approval and an additional two weeks for manufacturing.

Level 3: When working with a complex project or a custom design the order entry process will take 2-3 days, followed by 1-2 weeks for drawing approval and up to 3-5 weeks for manufacturing to be completed before shipping.

Delivery times vary on geography and are approximate and installation time will vary upon application.

Contact Soper’s today to determine the level of service required for your next project.

Why Use SoftWall?

You have an in-plant environmental problem – dust, fumes, noise, temperature, cross-contamination, odour, overspray, etc. You’ve considered hiring a contractor to build a traditional drywall, concrete block, or metal clad partition or enclosure. But, have you thought of installing a Soper’s SoftWall partition or enclosure? Consider the following advantages of a Soper’s SoftWall alternative to traditional rigid wall construction.

Cost

Traditional rigid wall construction can cost anywhere from $8 to $35 per square foot. Soper’s SoftWall systems cost a fraction of what it cost to build a traditional rigid wall, leaving extra money in the budget for other concerns. Don’t forget about low future modification costs, as well.

Flexibility

Traditional rigid wall construction is difficult to modify or move. Soper’s SoftWall partitions and enclosures can be easily disassembled and reinstalled or reconfigured elsewhere to accommodate new requirements.

Installation

Installing a rigid wall can be expensive, messy and time consuming. Soper’s SoftWall Partitions and Enclosures can be installed quickly with little or often no downtime, meaning minimal interruption to production. Plus, there is no mess and aggravation typically associated with rigid wall installs.

Call your regional agent and Soper’s for a more in-depth discussion!

Is your fabric flame retardant?

Yes.

When designing your custom solution, Soper’s can meet Class 1 ASTM E 84 or NFPA 701 flammability specifications and building code requirements by matching the right fabric to your application.

Both Canada and the United States uphold strict codes and regulations that determine classifications of flame retardant fabrics. There are many testing methods and agencies that perform these tests including the National Fire Protection Association (NFPA) and American Society for Testing and Materials (ASTM). It’s important to note that flame-retardant materials are not fire proof. Here are some material examples that are used in a few of our popular product lines:

| MATERIALS* | SPECIFICATION | USES |

|---|---|---|

| Vinyl Coated Polyester (VCP) | Select VCP materials meet NFPA-701, CAN/ULC-S109 and Class 1 ASTM E 84 flammability specifications | Soper’s SoftWall Enclosures, Partitions and Curtains |

| 14 mil Polyvinylchloride (PVC) Clear | PVC is a popular clear vinyl that is cost efficient, flexible, and durable and meets the NFPA-701 fire rating | Curtains, Partitions and Welding Screens(PVC is available in clear or welding colours) |

| Woven Polyethylene | Woven polyethylene fabric provides extremely high tensile and tear strength in relation to its light weight and meets NFPA-701 and Class 1 ASTM E 84 flammability specifications | Soper’s Curtains, Partitions and Fabric Air Ducts |

*Soper’s also carries a variety of specialty high temperature resistant fabrics

Contact Soper’s today for a more in-depth discussion!

Find a Distributor

Soper’s: your engineered fabric experts. We have over 140 years of expertise in designing solutions for commercial, industrial, and warehouse challenges, combined with a proven reputation for customer satisfaction. Our knowledgeable team will help answer your questions and find a solution tailored for your business. Soper’s runs a growing agent and distribution network across Canada and the United States. We look for strategic alliances to market our broad product mix across North America and the world.